| Home | Energy | Nuclear | Electricity | Climate Change | Lighting Control | Contacts | Links |

|---|

INTRODUCTION:

This web page is intended to introduce Fast Neutron Reactor (FNR) issues to individuals who have a basic science education but who know little or nothing about FNRs.

IMPORTANCE OF FNRs:

FNRs provide the only non-CO2 emitting technology that can sustainably and economically fully displace fossil fuels. FNRs operate by converting abundant fertile isotopes such as U-238 and Th-232 into fissile isotopes such as Pu-239 and U-233 faster than the fissile inventory is consumed. With suitable used fuel reprocessing FNRs can enlarge the natural fissile isotope supply more than one hundred fold. The 300 MWe/1000 MWt FNR detailed on this web site is intended for urban installation to provide sufficient electricity and comfort heat for about 100,000 people.

FNR DESCRIPTION:

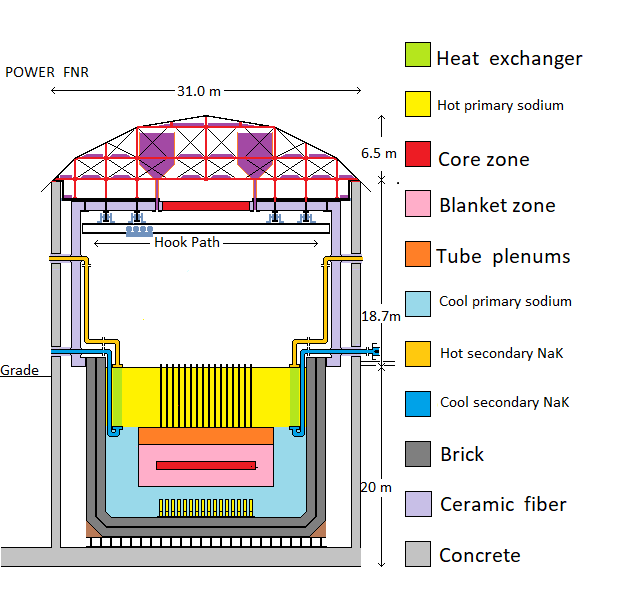

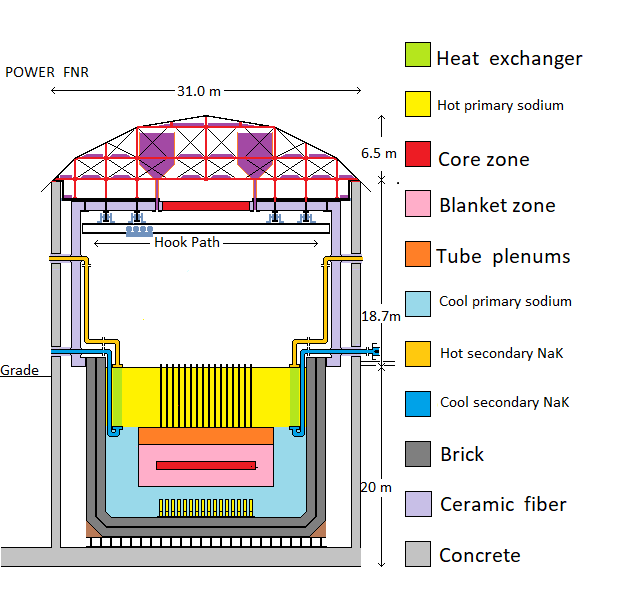

A FNR is simply a pool of liquid sodium, comparable in size to a swimming pool, which contains fully immersed bundles of end sealed vertical, (3 / 8) inch diameter, 0.036 inch wall chrome-steel fuel tubes. Inside the fuel tubes are stacks of metallic fuel rods formed from uranium-zirconium and uranium-plutonium-zirconium alloys. Also inside the fuel tubes is a small amount of liquid sodium that fills the narrow gap between the outside surface of the metallic fuel rods and the inside surface of the chrome-steel fuel tubes, providing a good thermal sliding connection between the fuel rods and the steel tube. Inside each fuel tube, above the top of the stack of fuel rods, is a gas space known as the fuel tube plenum.

The geometry of the fuel assembly enables a passive nuclear process which keeps the liquid sodium pool top surface at a nearly constant above ambient temperature. During normal FNR operation that temperature is typically set at 460 degrees C to 500 degrees C. The sodium surface is normally covered by argon gas to prevent sodium combustion.

In the event of loss of the argon cover gas the exposed top surface of the sodium pool can be covered by floating hollow steel spheres that reduce the exposed liquid sodium surface area and assist in air exclusion during sodium fire suppression.

The thermal power rating of a FNR is the rate at which heat can continuously be safely withdrawn from the liquid sodium pool by immersed intermediate heat exchange bundles located adjacent to the sodium pool walls. Since the sodium is heated by thermal conduction through the fuel tube walls the maximum thermal power rating of a FNR is limited by the total active core fuel rod length and by the maximum allowable temperature difference between the fuel rod centerline and the liquid sodium coolant outside the fuel tube wall.

FISSILE FUELS:

Fissile atomic isotopes such as U-233, U-235 and Pu-239 have the interesting property that when they capture a free neutron they usually fission. During each nuclear fission, in addition to fission products, a fissioning atom emits about 200 MeV of thermal energy and two to four free neutrons, each with a kinetic energy of about 2 MeV. These are known as fast neutrons. Fast neutrons have desirable properties in terms of efficient utilization of natural uranium, recycling of used nuclar fuel and disposal of nuclear waste.

Nuclear fission becomes a practical source of energy when there is a sufficient concentration of fissile atoms in close proximity to one another. Then neutrons emitted by one fissile atom can be captured by other nearby fissile atoms. Then the number of free neutrons N within the assembly of atoms will exponentially change over time in accordance with the formula:

N = No exp[R (t- to)]

where:

No = number of free neutrons in the assembly at time t = to;

and

R = a material, geometry and temperature T dependent parameter that can be either positive or negative. The parameter R is known as the fuel assembly reactivity.

At any instant in time the fission thermal power (heat per unit time) emitted by the assembly is proportional to N which governs the fission rate.

Note that if R > 0 the emitted thermal power rapidly increases, if R < 0 the emitted thermal power rapidly decreases and if R = 0 the emitted thermal power remains constant.

Thus power reactors are designed such that in normal steady state operation, at temperature T = To:

R ~ 0.

An FNR has the additional requirement that, due to themal expansion of the fuel assembly:

[dR / dT] < 0

Hence, when the fuel assembly temperature T rises above the setpoint temperature To the reactivity R becomes less than zero causing the fuel assembly to soon stop emitting fission heat. Assuming that there is a thermal load constantly removing heat from the sodium pool the fuel assembly will then start cooling. As the fuel assembly temperature T falls below the setpoint temperature To the reactivity again becomes positive causing the fuel assembly to soon emit much more heat. That heat will raise the fuel assembly temperature back toward To. These effects combine to cause the fuel assembly temperature to quickly converge to the fuel assembly setpoint temperature To.

FUEL ASSEMBLY GEOMETRY:

If the the assembly of fissionable atoms is shaped like a thin pancake the outside surface area of the assembly is large compared to its volume, so most of the emitted neutrons escape from the assembly without being captured by other atoms, making R less than zero, which causes N to exponentially decrease over time.

If the assembly of atoms is shaped like a sphere, which has a relatively small outside surface area as compared to its volume, then R can be greater than zero, which causes N to exponentially increase over time. That situation is known as a rapid chain reaction.

If the fissile atoms are distributed like two parallel flat thin pancakes sharing a common axis, then slowly bringing the two pancakes closer together and merging them makes their net behaviour change from being like two separate thin disks to being more like one single thick dense pancake. That is, as the two pancakes start to merge there is a separation distance at which R = 0.

We can build such an assembly at room temperature and immerse it in a pool of liquid sodium with the two fissile fuel pancakes separated. Then at time:

t = to

we can slowly move the two fissile fuel pancakes closer together which reduces their ratio of outside surface area to free neutron volume. As a result R becomes slightly greater than zero and the number of free neutrons exponentially increases causing a brief large increase in N and hence in the thermal power emitted by fission reactions. This thermal power heats the fissile fuel causing it and its related steel framework to thermally expand, so that the fissile atoms move further apart. In effect the ratio of surface area to volume of the assembly of fissile atoms increases with increasing temperature which reduces R back to below zero. This reduction in R stops the nuclear fission and hence the heat output. However now the fissile atoms are hotter than they were at time:

t = to

This behaviour is achieved by designing the fuel assembly such that at:

R = 0:

[dR / dT] < 0

We can gradually decrease the distance between the two fissile fuel pancakes until the assembly setpoint temperature rises to about 460 degrees C. At that point we have a created an elementary Fast Neutron Reactor (FNR). We can harvest its thermal energy output by extracting heat from the highly thermally conductive liquid sodium pool.

FNR NUCLEAR POWER PLANT (NPP) DESIGN CONSIDERATIONS:

The main appeal of an FNR with fuel reprocessing is that it is 100X to 200X more efficient in use of natural uranium than is a water cooled reactor.

Demonstration FNRs have been built since the early 1960s. FNRs cannot be directly cooled by water because the hydrogen in the water absorbs the fast neutron energy before sufficient fast neutron fission can occur. In a FNR the reactor coolant must be a substance that has sufficiently high atomic weight, is liquid over the reactor operating temperature range and has a low neutron absorption cross section. The possible coolant choices are certain liquid metals, certain metal eutectics and certain molten salts.

Molten salts have the disadvantages that their melting point is relatively high, their corrosion chemistry is complex and their fuel reprocessing chemistry is complex.

From a neutronic property perspective a lead-bismuth eutectic is likely the best FNR primary coolant. However, a lead-bismuth eutectic is toxic and neutron excited bismuth decays into polonium, which is one of the most toxic materials known to mankind. Hence, from a workplace health and safety perspective, a lead-bismuth eutectic in not an optimal FNR primary coolant choice.

The coolants used in most practical liquid metal cooled FNRs are either liquid sodium or liquid sodium-potassium eutectic (NaK). Sodium has a lower fast neutron absorption cross section than NaK, but Na melts at 98 degrees C whereas NaK is liquid down to below room temperature. In the reactor design discussed herein the primary coolant is sodium and the secondary coolant is NaK.

As compared to water, sodium as a primary coolant has several disadvantages:

a) Sodium chemically rects violently with water yielding heat and hydrogen gas, which spontaneously ignites in air. In a reactor environment the sodium must be covered with an inert gas, usually argon. Sodium cooled reactors are potentially very dangerous in marine applications.

b)An operating sodium cooled reactor produces Na-24 which decays to Mg-24 with a half life of about 15 hours. It is essential to do all necessary to ensure that if sodium ever burns or reacts with water producing Na2O or NaOH that these compounds be contained for at least a week before becoming air borne.Hence the sodium pool must be surrounded by a reliable secondary containment enclosure.

c)Furthermore, since sooner or later a steam generator tube will fail a sodium cooled NPP must safely manage the unexpected steam and hydrogen that will be injected into the secondary coolant loop.

d) Above 200 degrees C sodium spontaneously burns in air;

e) Sodium melts at about 99 degrees C;

f) The heat capacities of sodium and NaK are small as compared to water. Hence the temperature difference across a sodium or an NaK heat transport loop is typically four times the temperture difference for a similar sized water based heat transport loop. That large temperature difference can potentially cause large thermal stresses which must be carefuly managed.

g) In a neutron flux part of the sodium (Na-23) becomes Na-24 which has a half life of about 15 hours. That compares to neutron excited O-18 in water that in a neutron flux becomes O-19 that beta decays with a half life of 29 seconds to stable F-19. Hence neutron excited water becomes safe after about 5 minutes whereas neutron excited Na takes a week to become safe.

h)Thus, from a biosafety perspective, a nuclear reactor with water as the primary coolant is easier to service than a nuclear reactor with sodium as the primary coolant. This disadvantage can be greatly mitigated by suitable NPP design, but it is essential that a practical sodium cooled FNR NPP incorporate these essential design changes. Otherwise the NPP will likely financally fail due to operating at a low a capacity factor caused by combined thermal stress triggered leaks and larger shutdown times for service..

i) The initial fissile fuel concentration in a FNR is typically 5X the initial fissile fuel concentration in a light water cooled reactor. That initial fissile fuel concentration requirement has initial capital cost consequences.

FNR NUCLEAR POWER PLANT (NPP) FACILITY:

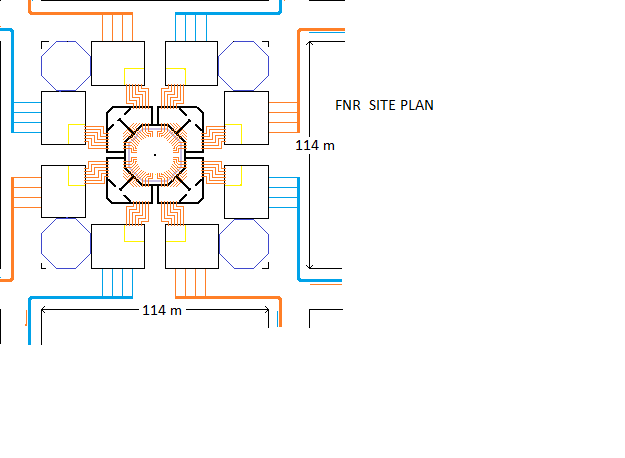

The web page titled: FNR Facility briefly describes the appearance of a FNR based nuclear power plant (NPP) that can be safely located in the middle of a population center of about 100,000 people to provide up to 300 MWe of electricity and up to 700 MWt of low temperature district heat.

A FNR NPP consists of three major systems:

a) The FNR and its enclosures;

b) The heat transport system which extracts heat from the FNR at a controlled rate and uses that thermal energy to form 10 MPa steam at 400 degrees C with a saturation temperature of about 320 degrees C;

c) A steam turbogenerator system with turbine bypass, associated condenser, heat sink, condensate injection pump, condensate heater, and related electrical switchgear.

Not including perimeter roads and nearby human support facilities, the FNR NPP above grade structures fully occupy one city block (a space 114 m X 114 m). The NPP footprint consists of a 50 m X 50 m central nuclear island with a 34 m diameter dome shaped roof. The nuclear island is separated by 10 m wide laneways from 12 surrounding structures. The structure heights vary from 20 m to 50 m above grade.

The sodium pool is centrally located, mostly below grade, in the nuclear island. Normally there is no personnel access to the sodium pool space because it is very hot, there is gamma radiation and there is no oxygen to breath. However, during reactor operation one can view the top of the sodium pool either through a thick window or via a video camera.

When the FNR is off and the sodium pool has cooled to about 120 degrees C and the Na-24 gamma ray emission has subsided equipment can be moved in and out of the sodium pool space via four airlocks.

The sodium pool is circular, 20 m inside diameter X 15 m deep, is located in the middle of a 26 m diameter cylindrica space. The liquid sodium surface is about 1 m below the pool deck and the ceiling is about 14.5 m ______above the pool deck. The liquid sodium is a low density metal that melts just below the boiling point of water.

In the middle of the sodium pool there is a 10.4 m diameter array of 464 vertical indicator tubes which, during normal reactor operation, project about 0.9 m above the sodium surface. These indicator tubes provide the actual elevations of the reactor's movable fuel bundles and the local sodium temperature. radiant temperature to ceiling mounted reactor monitoring systems. In the event of a ceiling or gantry crane collapse the indicator tubes also have a role in emergency safety shutdown.

Close examination of the sodium pool surface reveals a slight ripple because, when the reactor is producing power, natural circulation causes liquid sodium to rise in the center of the sodium pool and to sink near the sodium pool walls.

If the overhead lighting is extinguished, during normal reactor operation one may sense a faint near infrared glow, because normally the exposed surface of the sodium pool and the sodium pool enclosure are in the range 460 to 500 degrees C.

There are 96 X 16 inch dia radial pipes which cross horizontally over the pool deck and connect to the intermediate heat exchange bundles immersed in the sodium pool. These pipes contain a sodium-potassium alloy (NaK) which conveys heat captured by the intermediate heat exchange bundles to steam generators located in heat exchange galleries outside the reactor space.

High pressure (10 MPa) high temperature (400 degrees C) steam conveys heat from the steam generators to turbogenerator halls in nearby buildings. The turbogenerator related equipment converts about 30% of the transported heat into electricity and rejects the balance of the transported heat to a heat sink or district heating pipes. Note that the NaK pipes and steam pipes are all mounted so that they can thermally expand and contract without causing significant material stress.

At the pool deck level are four radial trays that are used, in combination with the air locks and an overhead polar gantry crane, to move fuel bundles and intermediate heat exchange bundles in and out of the reactor space. The inner air lock doors are located behind removable portions of the insulated side walls.

The nuclear island is very quiet. In most industrial installations there is a lot of background noise. However, inside the FNR nuclear island there are few mechanical moving parts. Within this building liquids move by natural circulation, by smooth induction pumping or by differential gas pressure.

If you listen carefully you may hear fan or blower noise from the ventilation system. The sodium pool and the various radial pipes are hot. In spite of good thermal insulation part of that heat leaks through enclosure walls, so to keep the human occupied service spaces comfortable forced air ventilation with closed circuit cooling is used.

In simple language the FNR passively supplies nuclear heat at a variable rate from 100 MWt to 1000 MWt. Near the sodium pool perimeter heat is extracted from 460 degree C surface sodium by cooler pumped NaK flowing through the intermediate heat exchange bundles. This heat extraction increases the density of the adjacent sodium causing it to sink. This cooler sodium sinking establishes a natural circulation flow pattern in the sodium pool. The sodium sinks near the pool perimeter and rises near the pool center. As a result of this natural circulation the temperature at the pool bottom center can fall to as low as 400 degrees C. The rate of heat generation by the nuclear process is proportional to the temperature difference between the fuel assembly bottom and the fuel assembly top which sets the sodium natural circulation flow rate. Note that about half of the circulating sodium bypasses the intermediate heat exchange bundles.

In principle the faster that the pumped NaK removes heat from the sodium the more electric power can be generated.

If the NaK flow stops the cooling of the sodium stops. Hence the sodium natural circulation flow stops which causes the nuclear fission to stop. After prolonged operation at 1000 MWt if the fission process is stopped the reactor continues to produce heat at about 80 MWt due to emission of fission product decay heat.

The design maximum power capacity of the FNR NPP is 300 MWe electrical, 700 MWt low grade thermal or 1000 MWt high grade thermal. In practical application during the summer most of the low grade heat rejected by electricity generation is discarded. However, in the winter up to 700 MWt of low grade heat is available for district heating. Generally this low grade heat should be used as the heat source for high COP water source heat pumps.

Note that the FNR sodium coolant discharge temperature is fixed at 460 degees C and the FNR thermal power output increases with increasing coolant flow. Induction pumps set the operating NaK flow rate. The heat transport system design prevents the sodium temperature at the bottom of the fuel tubes falling below 400 degrees C. This thermal power constraint limits the maximum heat flux through the FNR fuel tubes, which prevents metallic nuclear fuel center line melting and protects the fuel tubes from excessive heat flux.

A FNR has the virtue of rugged simplicity. However, a lot of work has gone into designing the FNR to safely tolerate both peripheral equipment failures and extreme events such as earthquakes, tsunamis, hurricanes, airplane impacts and terrorist attacks.

A practical FNR must be maintainable. Eventually the nuclear fuel will be consumed and it will be necessary to shuffle and/or recycle the nuclear fuel. If air leaks into the reactor space over time the oxygen and water vapor in the air will react with the liquid sodium forming a NaOH sludge with a melting point of 318 degrees C that should be filtered out of the liquid sodium.

Changes in thermal load cause thermal expansion and contraction of the NaK pipes and heat exchange bundles which cause long term wear. Internal pipe scouring causes further long term wear, eventually leading to equipment repair or replacement. Any suspended particulates in the heat transport fluids will aggravate long term scouring of the insides of pipes, fittings and heat exchange bundles. Hence, in spite of the apparent equipment simplicity, there are important ongoing maintenance considerations related to fluid cleanliness.

Note that there are 48 heat transport circuits, so various combinations of them can be shut down for service without impacting the performance of the remainder.

Most of the system ongoing maintenance is non-nuclear in nature and is related to the heat transport system, steam turbines, condensers, cooling towers, electricity generators, cooling water pumps and other non-nuclear electrical and mechanical equipment.

Normally the FNR itself can operate for months with minimal maintenance attention. The reactor power can be remotely adjusted by changing the induction pump set NaK flow rate. If anything in a heat transport circuit fails the simple solution is to turn off the corresponding induction pump and drain its NaK to its dump tanks until such time as competent maintenance personnel can attend to the problem. There is sufficient equipment redundancy to permit the FNR NPP to continue operation at slightly reduced power with some of its heat transport circuits and/or some of its turbogenerators out of service.

The liquid sodium pool operates at atmospheric pressure with argon cover gas. Unlike water cooled reactors there is nothing to blow up. If the induction pumps are turned off this reactor will passively default to its setpoint temperature. The main safety concerns are fire prevention by continuous exclusion of both air and water from the sodium pool space and ongoing removal of fission product decay heat.

SAFETY SHUTDOWN MECHANISMS:

A FNR is shut down by changing its fissile fuel geometry to reduce its reactivity.

A FNR has five independent shutdown mechanisms. One mechanism is passive thermal expansion which is used for normal ongoing temperature control. Two are also used for adjustment of operating temperature To and for scheduled shutdown for reactor service. Two are intended only for emergencies involving an unplanned overhead collapse, fuel geometry change, malicious sabotage or a military attack.

INTRODUCTORY GLOSSARY OF TERMS:

FNR: Fast Neutron Reactor;

NPP Nuclear Power Plant;

Fission: Splitting of an atomic nucleus;

Fissile Fuels: Materials that readily liberate nuclear energy via neutron capture induced fission;

Fission Thermal Power: Rate of heat generation caused by fission reactions in a nuclear reactor;

Reactivity R: A mathematical parameter which indicates the rate of change number of free neutrons in a nuclear reactor and hence loss or gain in fission thermal power;

Power Reactor: A nuclear reactor intended for producing electricity and/or heat;

Sodium: A highly thermally conductive highly reactive metal that melts at 98 degrees C;

Sodium Pool: A pool of liquid sodium about 20 m in diameter X 15 m deep which captures both the heat and radiation emitted by centrally contained nuclear fuel;

Indicator Tubes: Vertical metal tubes which project above the surface of the liquid sodium pool to convey movable fuel bundle position and local sodium temperature information to ceiling mounted electronic monitoring systems;

Hollow Stainless Steel Spheres: Buoyant stainless steel balls that float on the surface of the liquid sodium to reduce its exposed surface area and to assist in sodium fire asphixiation;

NaK: An alloy of the metals sodium and potassium that is liquid from below room temperature up to over 700 degrees C;

Intermediate heat exchange bundle: A bundle of metal tubes that transfers heat from the hot liquid sodium to slightly cooler but fully isolated NaK;

Induction Pump: A non-contact electromagnetic pump type used for circulation of NaK;

1000 MWt: One thousand million watts thermal (sufficient power to meet all the heat and electricity requirements of about 100,000 North American people)

This web page last updated October 30, 2025.

| Home | Energy | Nuclear | Electricity | Climate Change | Lighting Control | Contacts | Links |

|---|