TRU DEFINITION:

TRU is an acronym for TRansUranic actinides, which are atoms with atomic numbers greater than 92 that are formed when the

abundant uranium isotope U-238 is exposed to a thermal neutron flux.

Typically in used CANDU reactor fuel: the TRU concentration is about 4 grams / kg, about (1 / 2) of the TRU is Pu-239 and about (1 / 6) of the TRU is Pu-240.

APPLICATION:

TRU concentration is of interest to parties

that:

1) Have an inventory of used CANDU reactor fuel and who

would like to use that used fuel to make FNR fuel;

2) Have an inventory of used nuclear fuel from water cooled reactors and who

would like to mitigate the costs of transporting, storing and/or

reprocessing of that used fuel;

3) Have an inventory of used

nuclear fuel from water cooled reactors and who would like to rapidly

convert that used fuel into stable elements that pose no risk to

future human generations;

4) Seek to prevent nuclear weapon

proliferation or further nuclear waste formation via use of closed

system electrolytic fuel reprocessing (pyroprocessing) but who want to minimize the

overall cost.

THE ECONOMIC STRATEGY:

The economic fuel recycling strategy is to minimize the used fuel

reprocessing, shipping and storage costs by performing

relatively simple preliminary used fuel concentration operations on each CANDU power reactor site.

These preliminary

operations include:

a) Chopping up the used fuel into short lengths;

b) Prebaking the chopped fuel to expell and recover vapors and gases (Cs oxides + Kr + Ar +

Xe);

c) Harvesting the used Zr hulls;

d) Dissolving the used fuel in nitric acid;

e) Use of a cascade to divide the used fuel atoms into one large minimally radioactive UO2 portion

(90%) and one smaller highly radioactive portion (UO2 + FP + TRU)(10%) as required for

economic production of FNR fuel;

f) Acid recovery

TRU Concentration:

1) Minimizes the mass of CANDU fuel concentrates

that must be transported to a remote fuel reprocessing site;

2) Reduces the gamma emission from the extracted uranium oxide

sufficiently to make that uranium oxide more economic to transport

and store for future use as the main component of FNR blanket

fuel.

3) Enables complete disposal of TRU from used water cooled

reactor fuel, thus eliminating the necessity of DGRs for nuclear fuel

waste disposal;

4) Minimizes the used fuel mass that must be pyroprocessed;

TRU CONCENTRATION:

TRU concentration is a physical process that concentrates TRU by

selectively extracting nearly pure uranium oxide from used reactor fuel.

This web page describes an apparatus for concentrating the TRU in used

nuclear power reactor fuel about 10X. This apparatus uses a closed

recrystalization process

to separate the used nuclear fuel bundle atoms into three molecular

groups: pure UO2, Zr and everything else (UO2, TRU oxides, fission

products). This TRU concentration process is of fundamental

importance in economic production of fuel for Fast Neutron Reactors

(FNRs).

The largest used fuel portion, which comprises about 90% of the used nuclear fuel

weight, consists of nearly pure uranium oxide. The remaining high purity depleted

uranium oxide has a very low radioactivity and should be stored for

future use as FNR blanket rod material.

The ratios of the

uranium isotopes in this portion are determined by the neutron

irradiation history of the nuclear fuel. For used CANDU fuel this

portion has a very low radioactivity permitting relatively easy and

inexpensive handling, transportation, storage and reprocessing with

minimal gamma ray shielding requirements. Nearly pure UO2 extracted

from used CANDU fuel has a low radioactivity whereas UO2 extracted

from used Light Water Reactor (LWR) fuel has a higher radioactivity

due to the presence of a larger fraction of U-232. The required

amount of UO2 shielding is set by the U-232, U-235 and Np-237

concentrations in the uranium oxide as well as impurities. These

uranium isotopes will be present at low concentrations in the nearly

pure UO2.

The smaller

portion (10%) contains the balance of the used nuclear fuel weight.

For used CANDU fuel this portion is typically: oxides of U, TRU and

fission products. This portion is intensely radioactive and must be

handled and shipped in suitable shielded containers that

have walls that have a gamma ray absorption thickness the equivalent

of a 30 cm thickness of lead and must be stored in dry shielded

containers or vaults.

TRU CONCENTRATION OPERATIONAL OBJECTIVE:

Selective extraction of

uranium oxide should be done at existing CANDU reactor sites to

realize about 90% of the spent CANDU fuel weight as nearly pure

uranium oxide and the remaining 10% consisting of: (about 2.45% of

spent CANDU fuel weight as a mixture of fission products + TRUs) +

(remaining 7.55% of the CANDU fuel weight is uranium oxide).Â

The

uranium content of this mixture is used to meet the uranium metal

content requirement of the FNR fuel. The extracted nearly pure

uranium oxide must be sufficiently pure to reduce its radioactivity

sufficiently to enable low cost transportation and storage.

PROCESS OVERVIEW:

About 2010 Peter Ottensmeyer realized that there is a way of economically converting

used CANDU reactor fuel into FNR fuel with no spurious waste streams.

The method, now termed the Ottensmeyer Plan, has two major steps. The first major step is TRU concentration.

The second major step is pyroprocessing. This web page focuses on TRU Concentration.

TRU CONCENTRATION SUMMARY:

The TRU concentration operations

that need to be performed at each

CANDU power reactor site

include:

a) Chopping up the CANDU fuel bundles to expose the UO2

pellet material;

b) Baking the chopped up used fuel at 650 deg C in a

vacuum oven to drive off and capture Cs, other volatiles and the inert gas fission

products (FP);

c) Dissolving the residue in nitric acid to make

a warm saturated uranyl nitrate hexahydrate [UO2(NO3)2.6H2O]

solution;

d) Separating pure uranium nitrate hexahydrate from

other substances using a 13 stage recrystallization cascade;

e) Nitric acid recovery leaving a 90% pure UO2 pile and a 10% residue

pile.

PROPOSED MECHANICAL USED CANDU FUEL FEED:

a) From the used CANDU fuel inventory that has been

out of a CANDU reactor for at least 10 years withdraw used CANDU fuel

bundles as required.

b) Mechanically shear the used CANDU fuel

bundles into small pieces, each about 3 cm long.

VACUUM BAKING

2) Move the [U3O8 +

contamination Cs2O,Cs2O2, Cs2O3] from #1 above to a suitable furnace.

3) Heat the [U3O8 + contamination Cs2O,Cs2O2, Cs2O3] residue above

650 C to drive off the Cs2O, Cs2O2, Cs2O3 as a condensable gas. 4)

Condense and collect the radioactive Cs2O, Cs2O2, Cs2O3. 5) Send the

radioactive Cs2O, Cs2O2, Cs2O3 to fission product 300 year storage.

After 30 years in storage the radioactivity should be dominated by

Cs-137 (30 year half life) and Cs-135 (3.0 X 10^6 year half life).

Use a segragated store in case this material contains other

contaminants.

The main

reason for prebaking the uranium oxide is to exclude Cs-137 and inert

gases from the downstream dissolver. The

Cs isotope Cs-137 is strongly radioactive and should be trapped

during the prebaking and sent to 300 year storage. Also released

during prebaking are the inert gases krypton, xenon and argon that

were trapped within the used nuclear fuel pellets. Since some of the inert

gas isotopes are radioactive these inert gases must be safely

captured and vented far from a metropolis.

These gases can be

caught in an atmospheric pressure cold trap cooled by liquid

nitrogen. The relevant boiling points are:

|

GAS |

BOILING POINT |

|---|---|

|

Ar |

87.3 K |

|

Kr |

119.1 K |

|

Xe |

165.1 K |

|

CO2 |

194.7 K sublimation |

|

O2 |

90.2 K |

|

N2 |

77.3 K |

The cascade is fed by a closed dissolver. The dissolver has a heating coil and a removable fuel basket to enable removal of undissolved fuel and zirconium hulls. In normal operation the dissolver is always hot at 100 degrees C. The dissolver solution is saturated by maintaining an excess of used CANDU fuel. The dissolver receives HNO3 recovered from the two cascade outputs.

The dissolver has a heating coil and a removable fuel basket to enable removal of undissolved fuel and zirconium hulls. In normal operation the dissolver is always hot at 100 degrees C. The dissolver solution is saturated by maintaining an excess of used CANDU fuel. The dissolver receives HNO3 recovered from the two cascade outputs.DISSOLVER OPERATION:

a) The dissolver is a nitric acid resistant tank

with a removeable top. The dissolver tank contains a nitric acid

resistant basket to allow convenient zirconium hull recovery. An

empty basket is lowered into the dry dissolver tank, the dissolver

tank top is replaced and the dissolver tank is evacuated. This

evacuated air is exhausted to the atmosphere. The evacuation valve is

then closed.

b) Then hot nitric acid temporarily stored in the drain

down tank is pumped into the dissolver.

c) Due to the low overhead

pressure in the dissolver tank nitric acid containing a low UO2(NO3)2

concentration flows from the drain down tank into the dissolver where

it is heated to 100 degrees C. Used CANDU fuel is added to the

dissolver via a feed tube. After some time in the nitric acid at 100

degrees C in the dissolver solution becomes saturated with UO2(NO3)2.

Undissolved zirconium pieces collect in the dissolver's bottom

basket. Radioactive inert gas fission products such as krypton bubble

up through the liquid acid and collect in the sealed space above the

acid.

d) Then a controlled volume of the hot nitric acid solution is

pumped from the dissolver tank into tank T1 via the port at the

bottom of the dissolver. Sufficient nitric acid solution remains in

the dissolver tank over this port to prevent the radioactive inert

gas fission products on top of the dissolver solution from exiting

the dissolver via its bottom port.

e) Eventually when the inert gas

pressure over the acid in the dissolver tank becomes too high or when

the dissolver tank full of Zr hulls the dissolver is cooled to 20

degrees C to reduce the partial pressure of remaining HNO3 gas in the

dissolver head space.

f) The inert gas plus some HNO3 gas in the

dissolver head space are evacuated via a cold trap. The HNO3 vapor is

caught in the cold trap. The radioactive inert gases are sent either

to a high stack or to a pressure tank for later safe release to the

atmosphere at a remote location. Ideally the inert gas should be

stored to allow it to naturally decay. After a suitable decay period

vent the residual inert gas to the atmosphere. Note that radioactive

Kr-81, Kr-85 and Ar-39 must be well mixed with the atmosphere.

g) The

nitric acid in the cold trap is isolated and is recycled back to the

disssolver.

h) When the dissolver is full of Zr hulls the dissolver

is drained into the drain down tank.

i) The dissolver tank top is

removed. The basket containing zirconium pieces is removed from the

dissolver and is air dried. The neutron activated zirconium is

harvested from the dissolver basket for future use as a component of

FNR fuel.

j) Transport the neutron activated zirconium and the CANDU

fuel concentrates to the remote irradiated zirconium and fuel stores.

k) The now empty dissolver tank basket is replaced and the dissolver

batch cycle repeats. Note that the dissolver tank is sufficiently

large that one dissolver batch will serve many temperature cycles.

Note that as the system operates the amount of UO2 in the dissolver

gradually diminishes but the acid liquid level in all the tanks

remains almost constant and the UO2(NO3)2 concentration in the

dissolver solution remains almost constant. From time to time new

used CANDU fuel is added via the feed tube. Â

In the dissolver the irradiated zirconium hulls are captured in a basket for later use in FNR metallic fuel alloy. The neutron activated zirconium hulls were originally used in a CANDU reactor for enclosing the uranium oxide pellets used to fabricate CANDU reactor fuel bundles. Irradiated zirconium can be used in the FNR metallic fuel alloys to prevent the plutonium fraction of FNR core fuel from forming a low melting point Pu-Fe eutectic with the Fe fraction of the fuel tube alloy.

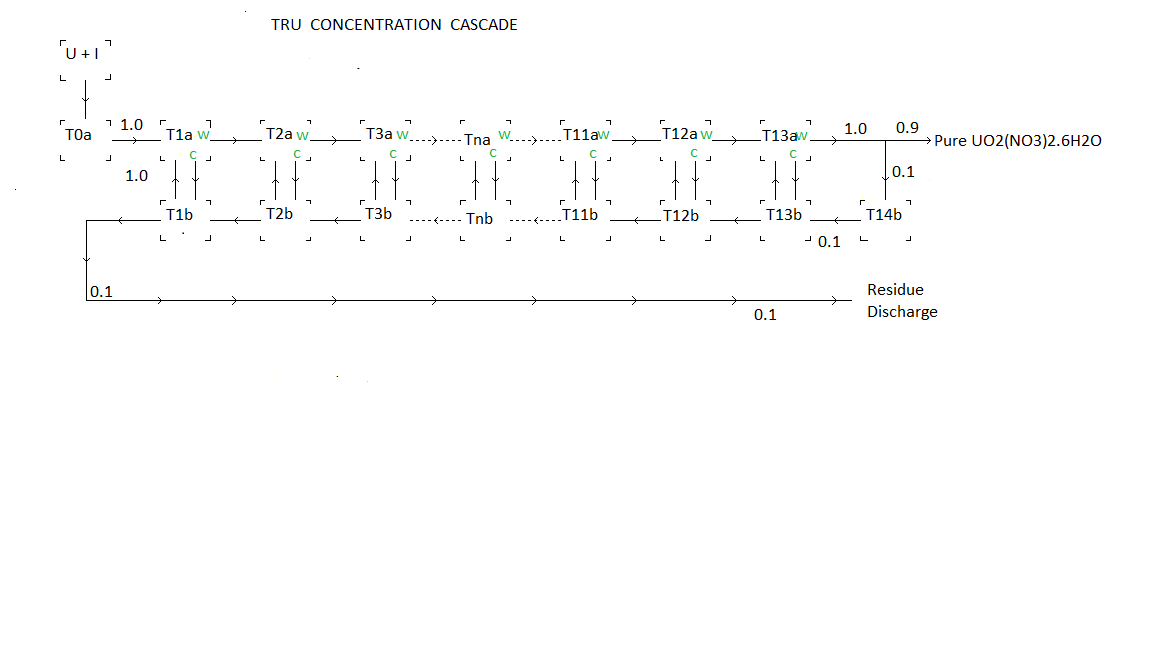

RECRYSTALIZATION CASCADE A 13 stage recrystallization cascade which divides the remaining used CANDU fuel into three portions:

The cascade

consists of a series of nitric acid resistant tanks designated by

Tnx. n = 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14 and x = a, b. The detail of the connections

to tank T13a, T14b and T1b differs from the other tanks to enable the

solution discharged by these tanks to properly feed the HNO3 recovery

apparatus.HNO3 RECOVERY

The extracted dissolver solution is heated to

evaporate the nitric acid which is recovered and recycled. A

significant amount of energy is required. The resulting dry residue

is the feedstock for successive operations to make FNR core fuel.

Very strong UO2(NO3)2.nH2O from tank T13a and T1b are transferred to the UO2

/acid recovery units. Heating this very strong solution to recover the

UO2 and the contained acid requires a

substantial amount of energy. The very strong solution in the UO2

/acid recovery unit is mildly heated to drive off the nitric acid

which is recycled.

THE NEPTUNIUM ISSUE:

For chemical reasons the TRU neptunium is not

excluded from UO2 during the uranyl nitrate hexahydrate

recrystallization process. This neptunium stays with the UO2 until ultimately it is fissioned in a FNR.

After TRU concentration, for public

safety reasons, the resulting fuel concentrates should then be

transported in shielded containers to a shared remote fuel

pyroprocessing site. The cost of transporting this used fuel portion is

dominated by the cost of transporting the weight of the required

shielded shipping containers. A major safety concern with respect to

this portion is ensuring that the used fuel concentrates will not go critical if

water penetrates the used fuel concentrates container.

Pyroprocessing involves electrolytic molten salt reprocessing of the residue to reduce the oxides to metals, to separate the concentrate components, to send fission products to 300 year isolated safe dry storage for natural decay and to fabricate suitably alloyed FNR fuel rods.

The fission

products are not waste. The fission products include rare earths that

are in high demand in the electrical industry. After 300 years in dry

storage the fission products will need further chemical processing to

extract the valuable elements.

REFERENCES:

For an overview of the Ottensmeyer Plan please review OTTENSMEYER

PLAN.

For an

overview of nuclear fuel waste processing see the paper:

Radioactive

Waste Partitioning and Transmutation.

Reference:Â Japanese

2002 patent

For an

overview of Uranyl nitrate hexahydrate [UO2(NO3)2.6H2O] solubility

see:

Uranyl nitrate

hexahydrate solubility in nitric acid and its crystallization

selectivity in the presence of nitrate salts

A paper on

decontamination factors actually realized is:

Enhancement of Decontamination Performance of Impurities for Uranyl

Nitrate Hexahydrate

A paper

relevant to the U-232 issue is:Â

Uranium-232 Production In Current Design LWRs

Other relevant papers are:

Actinide Partioning Technologies

and

Extraction Selectivity

UO2(NO3)2 SOLUBIlITY IN NITRIC ACID:

0 deg C = 98 g / 100 g H2O

20 deg C = 122 g / 100 g H2O

100 deg C = 474 g / 100 g H2O

The imporance

of this data is that when a saturated uranyl nitrate hexahydrate

solution at 100 deg C is cooled to 20 degree C the weight of crystals

formed per 100 g H2O will be:

474 g - 122 g = 352 g

The initial

solution weight

474 g + 100 g = 574 g

Thus more than 50% of

the initial warm solution weight forms crystals.

Note that there is little merit in further increasing the weight fraction of crystals because, while in theory that reduces the requred number of stages, it sacrifices crystal face washing by the remaining liquid solution.

Email from

Peter:

Off the top of my head uranium nitrate hexahydrate

dissolves in water up to about 66 %, i.e. it is not solid UNH but

diluted with the 34% water. When it crystallizes out it has a density

as a solid of about 2.8 g/cc whereas the density of the solution is

roughly

2.8 x .66 + 1.0 x .34 or about 2.2.

Therefore I expect

the crystals that form spontaneously to sink.

However, if a cold

surface is introduced into the hot solution, then I would expect the

crystals to form on the cold surface and stick there (depending on

the properties of that surface) until they are scraped off.

Â

RECRYSTALLIZATION

PURIFICATION OPERATING PRINCIPLE:

The dissolver temperature is

kept at 100 degrees C, the dissolver solution is saturated by

maintaining an excess of used CANDU fuel in the dissolver tank.

Assume that a

measured amount of solution from the dissolver tank is transferred from tank T0a

to Tank T1a.

Assume that we start with tank T1a holding a

uniform warm saturated liquid HNO3 solution that contains multiple

solutes. Assume that one solute So (uranyl nitrate hexahydrate) is

dominant. The other non-dominant solutes are S1, S2, etc. From the

perspective of the dominant solute So the fraction of each impurity

Sn is:

(Sn / So).

If the solution is gradually cooled it will

form dominant solute crystals surrounded by liquid solution

containing the lesser solutes. We need the dominant solute crystal

formation rate to be sufficiently small that the resulting dominant

solute crystals are sufficiently large that their discharge from the

tank can be mostly prevented by use of a simple grating or course

filter. Now drain off the cool liquid solution portion in Tank T1a to

Tank T1b. Use a course filter on the cool solution drain line to

prevent the crystals flowing out the drain.

The crystals

are highly regular atomic structures. During dominant solute crystal

formation within a saturated liquid solution mamy of the impurities

tend to be excluded from the dominant solute crystal and hence will

accumulate in the surrounding liquid and on the crystal faces. It is

important to maintain solution agitation sufficient to continuously

wash the impurities off the crystal faces. If, after dominant solute

crystal formation, the surrounding liquid is drained off the excluded

impurity concentration in this drained off liquid is about:

(Sn / Sob)

where Sob is the portion of So in the drained off liquid and

the concentration of impurity Sn in the crystals is close to zero.

Now assume

that it is physically practical to make the weight of dominant solute

crystals about equal to the weight of drained off liquid at 20 degrees C. Then:

Sob ~ (So / 2)

The impurity

concentration in the drained off liquid is:

[Sn / Sob]

= (Sn / So)(So / Sob)

~ 2 (Sn / So)

Now warm up the crystals remaining in tank T1a. They are nearly pure with respect to exclusion of impurity Sn. Drain out this liquid to another tank T2a via a micron filter. This filtrate is very pure. The purpose of the micron filter is to try to trap in the tank T1a impurities that were incorporated into the solid crystal but not chemically bound. These impurities will tend to drain out to tank T1b via the course filter at the next opportunity.

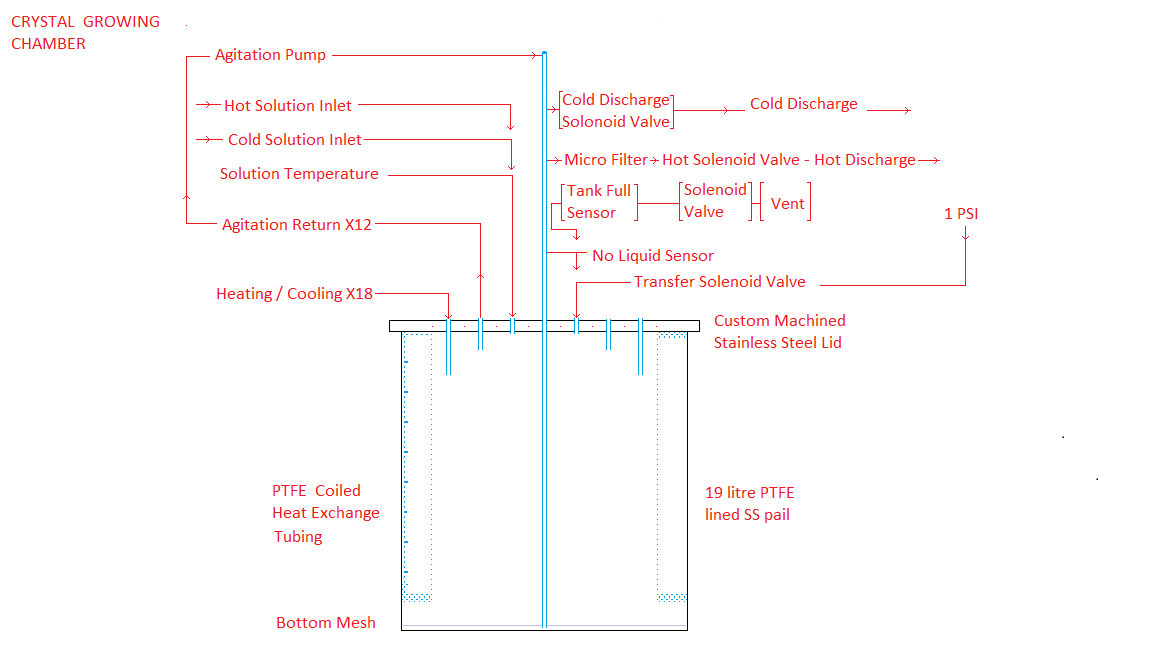

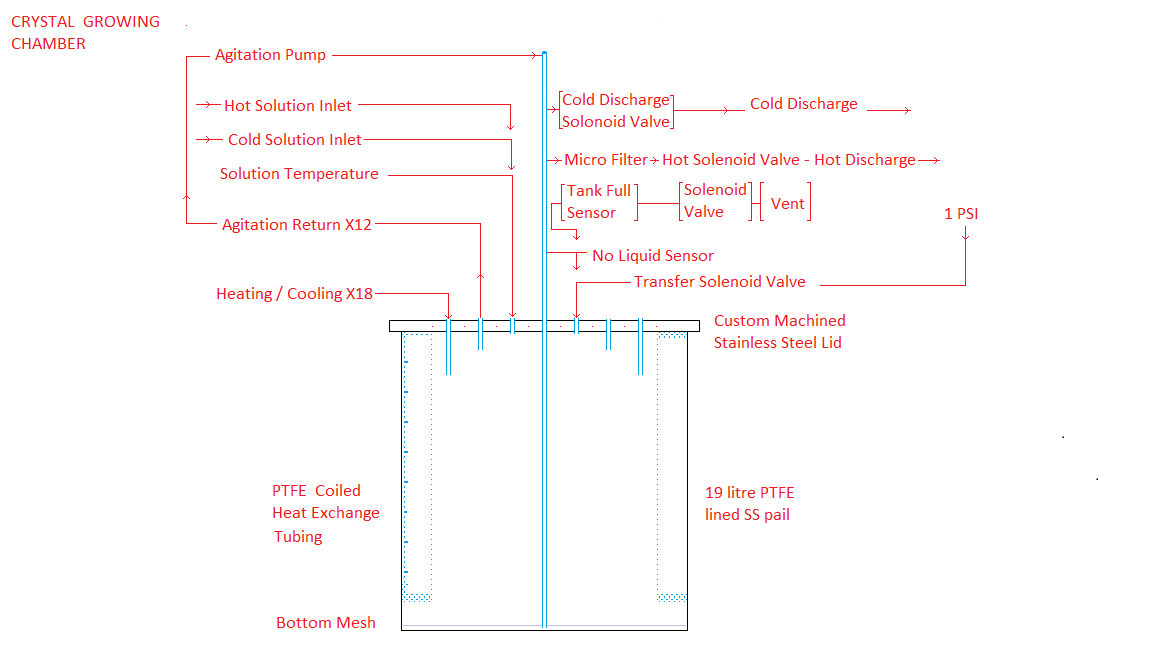

A detailed

description of the design and operation of a typical Tank Tna containing the Uranyl Nitrate

Hexahydrate automatic crystal growing chamber is set out at:

Uranyl

Nitrate Hexahydrate Crystal Growth

RECRYSTALLIZATION PROCESS CONSTRAINTS:

1) The process equipment must not be so

large that a critical mass can accumulate anywhere in the apparatus.

We must be careful with respeect to tank T1b where the impurity concentration is

highest.

2) Nitric acid (4.5 M) acting on uranium oxide produces

uranyl nitrate hexahydrate. The process of recrystalization of uranyl

nitrate hexahydrate [UO2(NO3)2.6H2O] is used to selectively extract

nearly pure UO2 from spent CANDU fuel. This process is ineffective at

rejecting the elements Np and Cs. The Np simply stays mixed with the

uranium. It is not a radioactivity problem unless it contains the

isotope Np-237. Np-237 arises from fast neutron n > 2n reactions

in U-238. In CANDU reactors the fast neutron flux is very low, so the

Np-237 production is low so the contribution of Np-237 to spent fuel

radioactivity is very low. This statement is not true for spent fuel

from fast neutron reactors. Hence recrystalization of

[UO2(NO3)2.6H2O] will not achieve comparable radioactivity reduction

in FNR spent fuel.

3) The process of

recrystalization of [UO2(NO3)2.6H2O] is also ineffective at rejection

of CsNO3.2H2O from the crystals. Before the recrystalization steps Cs

is rejected by baking the uranium oxide at over 650 degrees C at

which point the isotopes Cs-133, Cs-135 and Cs-137 vaporize as the

oxides Cs2O, Cs2O2, Cs2O3 leaving behind U3O8 with some contaminant

Np. These vapors must be condensed in a cold trap. As indicated above

the contaminant Np is not a problem unless it contains Np-237 from

fast neutrons interacting with U-238.

4) During the initial

prebaking most of the trapped radioactive Kr-81, Kr-85 and Ar-39

inert gas atoms are released in the vacuum furnace. This trapped

inert gas mixture must be captured, condensed, stored, transported,

separated from Cs, adequately mixed with the atmosphere and safely

vented.

5) There must be a mechanism to safely prevent

uncontrolled release of any remaining inert gases or Cs while new UO2

is being added to the dissolver tank.

CHEMISTRY:

U3O8

= UO2 + 2 UO3

UO2 + 2 HNO3 + 6 H2O = UO2(NO3)2.6H2O + H2 + heat

UO3 + 2 HNO3 + 5 H2O = UO2(NO3)2.6H2O

UO2(NO3)2.6H2O + heat = UO3 + 2 HNO3 + 5 H2O

DEFINITIONS:

The

term weak solution refers to a UO2(NO3)2 4.5 M nitric

acid solution which is saturated at 20 degrees C. The term strong

solution refers to a UO2(NO3)2 4.5 M nitric acid solution which

is saturated at 100 degrees C.

HYDRATION OF UO2(NO3)2:

According to Wiki UO2(NO3)2.nH2O exists as a

dihydrate, a trihydrate and a hexahydrate. It appears that unless

concentrated nitric acid is used the result will be the hexahydrate.

However, when the hexahydrate is gradually heated during UO2 recovery

the hexahydrate may liberate water molecules to form the trihydrate

and then dihydrate forms.

The components and design of this crystal growing chamber are described at:

Uranyl Nitrate Hexahydrate Crystal Growth

Typically in

real life a single stage of separation gives:

A ~ 0.95

and

B

~ 0.05

Recrystalization separation factor = (A / B) ~ 19

As (I / U) rises the rejection of impurities on crystal formation becomes less ideal. Impurities that chemically bond with the uranium nitrate hexahydrate are not rejected.

RECRYSTALIZATION CASCADE DESCRIPTION:

The main

apparatus used for selective uranium oxide extraction is a nitric

acid dissolver followed by a thirteen stage uranyl nitrate hexahydrate

recrystallization tank cascade.

The mixed input to the cascade is

(U + I) = uranyl nitrate hexahydrate solution

Im =

impurities (fission products and TRU)

CASCADE OVERVIEW:

In operation hot strong acid solution saturated with

UO2(NO3)2 at 100 degrees C is fed from the dissolver into tank T1a

and cool clean acid solution saturated with UO2(NO3)2.6H2O at 20

degrees C is later generated in tank T13a. As the dissolved used CANDU

fuel moves from tank column 1 to tank column 13 it converts from being

97.55% UO2(NO3)2.6H2O to being nearly pure UO2(NO3)2.6H2O. The

initial impurity fraction in used CANDU fuel is:

2.45% impurity to about 24.5% impurity.

The equipment

consists of a dissolver, tanks Tnx where n = 1,2,3,4,5,6,7, 8, 9, 10, 11, 12, 13, 14 and x =

a,b and two UO2 / acid recovery units. The dissolver contains

100 degree C saturated solution with an excess of used CANDU fuel. The

system goes through a series of temperature oscillations each

consisting of a slow cooling period from 100 degrees C down to 20

degrees C (320 minutes) followed by a more rapid heating period from

20 degrees C back up to 100 degrees C (80 minutes). After each

heating period clean hot solution is transferred one tank to the

right. During the subsequent cooling and crystal growth period TRUs +

FP are rejected from the crystals to the liquid. At the end of each

cooling period the remaining liquid solution flows down to tank Tnb

carrying the rejected impurities toward the impurity output. We can

refer to each complete module temperature oscillation as a

temperature cycle. Due to cleaner solution feedback the solution fed

back to tank Tna is cleaner than the solution that flowed into Tank

Tnb.

CASCADE

DESIGN:

The cascade is designed so that the Tna row tanks

operate at progressively higher purities going to the right and the Tnb row tanks operate at higher

impuity concentrations going to the left. At the end of each heating

period solution is transferred one tank to the right sequentially starting with T13a. While liquid transfers are occurring the liquid volume

in the individual tanks changes.

The tank temperatures are

programmed to oscillate, typically between 20 degrees C and 100

degrees C. The circulated heating oil reaches up to 120 degrees C for

warming and reaches down to 15 degrees C for cooling.

The heating can be relatively fast (~ 1.0 degree C /

minute) but the cooling must be relatively slow (~ 0.25 deg C / minute). The required fine temperature control is

achieved by controlling the circulated oil temperature. During a tank

cooling periood UO2(NO3)2.6H2O crystals tend to grow on the textured

bottom surface but not onthe teflon surfaces.

INTERTANK LIQUID TRANSFERS:

Intertank liquid transfers are realized by

applying one psi air pressure over the upstream tank while venting the

downstream tank. There are two types of intertank liquid transfers.

One type of intertank transfer stops the liquid transfer when the upstream tank indicates that it contains no more liquid. This type of liquid transfer is used when there are solid crystals remaining in the upstream tank. In this case a liquid sensor is mounted on the common liquid discharge tube. When thiss sensor detects no liquid the liquid transfer is complete. Such a liquid transfer from tank T1a to tank T2a is indicated by: Transfer T1a, T2a, NL (No Liquid).

The other type of liquid transfer stops the transfer when the downstream tank indicates that it is full. This type of transfer is used when the upstream tank is intentionally not fully emptied. The downstream tank full sensor is mounted on its vent tube upstream of the vent solenoid valve. Such a transfer from tank T3b to tank T3a is indicated by Transfer T3b, T3a, DF (downstream full).

TANK T1a TO TANK T2a SOLUTION TRANSFER SUBROUTINE, UPSTREAM NO LIQUID DETECTION:

A liquid transfer from

tank T1a to tank T2a is achieved by:

a) Stop solution agitation in

tank T1a;

b) Open the NO top vent valve on the top of tank T2a;

c) Open the NC warm liquid discharge valve branch off the discharge

tube of tank T1a;

d) Close the NO top vent valve on tank T1a;

e) Open the NC transfer air pressure valve on the top of tank T1a;

f) Wait for tank T1a no liquid sensor to indicate empty for one full second;

g) Close the NC transfer air

pressure valve on the top of tank T1a;

h) Open the air vent valve on tank T1a;

i) Close the NC warm liquid discharge valve branch off

the common teflon discharge tube of tank T1a;

TANK T3b TO TANK T3a SOLUTION TRANSFER SUBROUTINE, DOWNSTREAM TANK FULL DETECTION:

A liquid transfer from

tank T3b to tank T3a is achieved by:

a) Open the NO vent valve on the top of tank T3a;

b) Open desired NC liquid discharge route valve branch off the main discharge

tube of tank T3b;

c) Close the NO vent valve on tank T3b;

d) Open the NC transfer air pressure valve on the top of tank T3b;

e) Wait for tank T3a to indicate full for 0.2 seconds;

f) Close the NC transfer air

pressure valve on the top of tank T3b;

g) Open the air vent valve on tank T3b;

h) Close the NC main liquid discharge valve off

of tank T3b;

CASCADE FORMATION:

The cascade is formed by sequentially connecting thirteen crystal growing stages with residue feedback.

The cascade operates by taking advantage of the temperature dependence of UO2(NO3)2 solubility in 4.5 M HNO3. Lowering the temperature of a saturated solution triggers recrystallization. During slow recrystallization impurity atoms are excluded from the UO2(NO3)2.6H2O crystals and concentrate in the surrounding liquid solution. In order to realize high purity UO2(NO3)2.6H2O a cascade containing thirteen successive recrystalization steps is used. At low temperatures about half of the solution forms solid crystals. At high temperatures the solution is saturated but there are no solid crystals.

The tanks Tna all oscillate in temperature together. During a Tna cooling period crystals form in the tanks Tna. During the cooling period part of the solution in tank Tnb is shifted into tank T(n-1)b. At the end of a cooling period liquid solution remaining in Tank Tna is transferred into tank Tnb. During the subsequent warming period the crystals remaining in in tank Tna melt. At the end of the warming period this pure solution is transferred right into tank T(n+1)a. Then part of the solution in tank Tnb is shifted into tank Tna.

During steady state operation the fraction:

(TRU + FP) / U at the cascade residue discharge builds up to be about

10X the (TRU + FP) / U fraction in the dissolver, which

fraction is three orders of magnitude higher than the corresponding

value of (TRU + FP) / U at the nearly pure uranium oxide discharge.

CASCADE OPERATION: Tanks

Tna, which each accommodate a solution volume of at least 2 U, oscillate in temperature. During a cooling period crystals form in tanks Tna. During a warming period these crystals melt. The normal operation initial condition is that when full each of tanks Tna contain 2 U of hot saturated solution and each of tanks Tnb contain (U / 10). During the period during which tanks Tna are cooling solution amount (U / 10) is shifted left one position in tanks Tnb starting with T1b and moving to the right to T14b so that at the end of this solution shift sequence tank T14b is empty. Tank T1b discharges (U / 10) to the cascade residue output. The amount (U / 10) is indicated by total discharge of each upstream tank into the next downstream tank as indicated by no liquid in the liquid transfer circuit. The amount U / 10 is set by a measured amount of solution that enters tank T14b which amount is set by the T14b full indicator. Wait until all tanks Tna reach the desired low temperature (20 deg C). At the end of the cooling period all of

the remaining cool liquid in each tank Tna (approximate volume U in each tank) is transferred to the accompanying tank Tnb. Note that tanks Tnb must each accommodate a volume of more than 1.1 U. This transfer occurs until each upstream tank Tna is dry as indicated by no liquid in the common liquid transfer circuit. Then tanks Tna and Tnb are both warmed. During a warming period the solid crystals in tanks Tna melt. Wait until all tanks reach the desired high temperature (100 deg C). Then moving from right to left the warm saturated solution of volume U is completely discharged to the next a tank T(n+1)a as indicated by no liquid in the liquid transfer circuit. The volume (U /10) of the liquid discharged from the last tank T13a is discharged to tank T14b as indicated by a liquid level sensor in the T14b vent line and the then the remaining (9 U /10) is discharged to the

UO2(NO3)2.6H2O cascade output. Volumed U of new saturated solution flows from tank T0a into tank T1a. In each case no liquid in the common liquid transfer line indicates complete transfer. The volume in Toa is indicated by a liquid level sensor in its vent line. Then the warm liquid in tanks Tnb for n = 1 to 13 is transferred into tanks Tna where it is mixed with the newly shifted in liquid

from tanks T(n-1)a so that tanks Tna all contain 2 U of solution. Completion of this liquid transfer is indicated by tank full sensors in the vent lines of tanks Tna. Note that the liquid insertion amount U flowing from tank T0a and recirculated amount (U / 10) flowing from tank T14b are accurately calibrated. SOLUTION SHIFTING SUMMARY: About 90% of the solution resulting from melting

the remaining crystals in tank T13a is transferred into the pure UO2(NO3)2.6H2O output and then the UO2 / HNO3

recovery.

While a tank Tna is being heated or cooled there is

no solution flow in or out of tank Tna. During the cooling period crystals

form which increase the residue concentration in the liquid

surrounding the crystals. At the end of the cooling period crystals

containing nearly pure uranium nitrate hexahydrate are retained by a

screen and the surrounding cool liquid is transferred to tank Tnb.

Then tank Tna is heated. The

UO2(NO3)2.6H2O crystals remaining in tanks Tna melt.

After a warming period, starting from the right, there are successive

warm liquid discharges from tank Tna to tank T(n+1)a toward the nearly pure uranium discharge.

Then starting from the right tank Tna is reloaded from tank T(n-1)a. Then the tank Tna is

reloaded from tank Tnb. Then another cooling period

commences. During this period solution volume (U / 10) is left shifted out of the Tnb tanks starting from the left.

CASCADE MATHEMATICS:

A practical

cascade design is one where recrystallization at each stage is

assumed to be imperfect. Assume that the weight of crystals = weight of solutution at the lowest temperature. Then the single stage transfer function is:

U + I = [(U / 2) + A I] + [(U / 2) + B I]

where cool output flow per thermal cycle is:

[(U / 2) + A I]

and where warm output flow per thermal cycle is:

[(U / 2) + B I]

where:

A + B = 1

U = total uranium nitrate hexahydrate stage input

I = total impurity stage input

CASCADE BOUNDARY CONDITIONS:

Cascade input = (U + I)

Cascade main discharge = (9 / 10)(U) + k I

k < (1 / 1000)

Cascade residue discharge = (U / 10) + (1 - k) I

Ideally with

an infinite number of stages k = 0 so the residue discharge flow

is:

(U / 10) + I

For each Tnb stage for n = 1 to 13:

Main output = 10 X Aux output

For tank T1b:

Main output = 10 [(1 / 10)(U) + (1 - k)(I)]

= U + 10 (1 - k) I

Cascade Separation Factor:

[(I / U)] / [k (I /U)]

= [1 / k]

FLOWS

FIRST STAGE ANALYSIS:

Tank T1a Main input = (U + I)

Tank T1a Aux input = 10[Residue discharge]

= 10 [(1 / 10)(U) + (1 - k)(I)]

= (U) + (1 - k) (10 I)

T1a total input = 2 U + (11 I) - k (10 I)

T1a warm output = (U) + B I[(11) - 10 k]

T1a cool output = (U) + A I [(11) - 10 k]

Tank T1b Main input = (U) + A I [(11) - 10 k]

Tank T1b Aux input = (U / 10) + K2 I

Tank T1b Total input = (11 U / 10) + A I [(11) - 10 k] + K2 I

Tank T1b Aux input = (Tank T1b total input - Tank T1b main input)

= (11 U / 10) + A I [(11 ) -10 k] + K2 I - [(U) + A I [(11) - 10 k]]

= (U / 10) + K2 I

K2 ~ (1)

Tank T1b Total input = Tank Tib total output

or

(11 U / 10) + A I [(11) - 10 k] + K2 I

= (11 U / 10) + (1 - k) 11 I

or

A I [(11) - 10 k] + K2 I = ( 1 - k) 11 I

or

A [(11) - 10 k] + K2 = (1 - k) (11)

or

K2 = (1 - k)(11) - A [(11) - 10 k]

= 11 (1 - k - A) + 10 k A

= 11 (B - k) + 10 k A

= 11 B - 11 k + 10 k A

= 11 B - k - 10 k + 10 k A

= 11 B - k - 10 k (1 - A)

= 11 B - k - 10 k B

For the

special case of many stages then:

k = 0:

giving:

K2 I = (11) I (1- A)

= (11 / 2) I B

which, as expected, is the same as the impurity carried forward via the T1a warm discharge.

The effective first stage separation factor is:

(I / U) / [B I ((11) - 10 k) / (U)]

= 1 / [B (11 - 10 k)]

which for k = 0 becomes:

1 / [B (11))]

= 1 / 11 B

which for B ~ (1 / 20) becomes:

20 / 11

LAST STAGE ANALYSIS:

Tank Ta Main Input = Tank Ta Total Input - Tank Ta Aux Input

= Tank Ta Total Output - Tank Ta Aux Input

= 2 U + I - [U + (10 / 11) A I + (B I/ 11)]

= U + I - (10 / 11) A I - (B I/ 11)]

Tank Ta Aux Input = Tank Tb main output

= U + (10 / 11) A I + (B I/ 11)

Tank Ta warm output = U + B I

Tank Ta cool output = U + A I

Tank Ta total output = 2 U = Tank Ta total input

Tank Tb Main Input = U + A I

Tank Tb Aux input = (U + B I) / 10

Tank Tb total input = (11 / 10) U + A I + (B I / 10)

Tank Tb Main Output = U + (10 / 11)[A I + (B I / 10)]

= U + (10 / 11) A I + (B I/ 11)

Tank Tb Aux output = (U / 10) + (A I / 11) + (B I / 110)

Last stage separation factor:

[I - (10 / 11) A I - (B I / 11)] / (B I)

= (1 / B) - (10 / 11)(A / B) - (1 / 11)

= (1 / B) - (10 / 11)((1 - B) / B) - (1 / 11)

= (1 / 11 B) + (9 / 11)

For B = (1 / 20):

Last stage separation factor = (29 / 11)

Thus about 13 stages, each with two tanks, will likely be required to reduce the

Pu impurity concentration in the UO2 by a factor of 1000.

FIRST STAGE

OVERVIEW: The contents

of Tank T1b are heated to 100 degrees C and 1 U of this liquid is recycled back into tank T1a. Then 1 U of the contents

of tank T0a are transferred into tank T1a.

Tank T1a then

starts a new cooling cycle.

The full cascade converts 90% of the from being 97.55%

UO2(NO3)2.6H2O to being nearly pure UO2(NO3)2.6H2O. The initial

impurity fraction in used CANDU fuel is: 2.45%. The impurity

fraction at the cascade residue discharge is ~ 24.5%.

The cascade

consists of a series of nitric acid resistant tanks designated by

Tnx. n = 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14 and x = a, b. The detail of the connections

to tank T13a, T14b and T1b differs from the other tanks to enable the

solution discharged by these tanks to properly feed the HNO3 recovery

apparatus.

The tank

discharge tubes are fed from the very bottom of each tank. The

discharge connections to the adjacent downstream tanks are to the

space above the liquid levels in the downstream tanks to ensure that

there are liquid breaks in the connections between adjacent tanks.

Each tank's overhead gas space is vented via a liquid detector and a NO solenoid valve to a common overhead vent

pipe. This solenoid valve is sometimes closed to permit easy liquid transfer

between tanks while safely containing hot HNO3 and related gases.

The tanks Tna

are all weakly agitated during crystal growth by circulating solution so

that there is rising solution convection within the UO2(NO3)2.6H2O

solution. The purpose of the weak agitation is to minimize impurity

accumulation on the crystal faces during crystal growth and to

prevent common drain blockage by small crystals.

Each tank has a

temperature sensor which is used to monitor the heating/cooling

rates and to indicate when a heating or cooling cycle is complete.

During the

heating period the temperature of the circulated oil is about 20 degrees C

warmer than the temperature of the solution. During a cooling

period the temperature of the circulated oil is about 5 degees C cooler than the

solution.

At the end of

the heating and cooling periods the solution in each tank is

transferrred into the next downstream tank.

Absent U-232

in the used fuel this cascade should reduce the uranium oxide gamma

emission per kg down to the level of new CANDU fuel formed from

natural uranium_______??. The amount of U-232 gamma emission will be

a strong function of the original Th-232 impurity concentration in

CANDU fuel and a weak function of the age of the used CANDU fuel. During an

intertank solution transfer each transfer normally runs until either the downstream tank is full or there

is no liquid in the upstream tank.

The tanks all

have liquid level full sensors and common drain tube empty sensors.

There is

control logic which will stop the liquid transfer sequence and alarm

if any tank liquid level exceeds its design maximum. The floor under

the tanks is covered with an acid resistant stainless steel sheet which

is sloped to a common acid drain. The drain goes to a basement level

dirty acid drain down tank. Thus any acid leak anywhere in the system

gravity drains into this dirty acid drain down tank.

CASCADE MAINTENANCE:

The cascade

requires drain and rinse valves at each end to enable cascade draining and

flushing. UO2(NO3)2 SOLUBIlITY: The amount of CANDU fuel processed per thermal cycle

is: Mass per tank per 100 g

H2O that must be heated and cooled in each thermal cycle is: TANK VOLUMES: HEAT REQUIRED TO DRIVE ONE THERMAL CYCLE OF OPERATION: Heat of formation of UO2(NO3)2.6H2O: Heat capacity of H2O = Heat capacity of UO2 = Heat capacity of HNO3 = Latent heat of vaporization of water = Volume of each tank =

In operation hot strong acid solution saturated with

UO2(NO3)2.6H2O at 100 degrees C is fed from the dissolver into tank

T1a main inlet. Tank T1a is then cooled to 20 degrees C. The

remaining cool liquid is transferred from tank T1a to tank T1b.

The remaining solid UO2(NO3)2.6H2O in tank T1a is then warmed. After crystal melting the nearly pure liquid is shifted into tank T2a.

To enable system maintenance the dissolver basket

containing remaining fuel and zirconium hulls is removed and placed

behind a shielded barrier, all the tanks are heated to 100 degrees C

to fully dissolve the remaining solids and then the entire system

solution volume is shifted and drained down into the shielded below grade acid

drain down tanks. Below the drain down tanks are pumps which can be

used to transfer the acid solution back into the cascade after the

service work is complete.

0 deg C = 98 g / 100 g H2O

20 deg C = 122 g / 100 g H2O

100 deg C = 474 g / 100 g H2O

Solute mass

per 100 g H2O that moves one tank forward with each thermal cycle:

(474 g - 122 g) / 100 g = 352 g UO2(NO3)2 / 100 g H2O

[UO2 / UO2(NO3)2] X 108 g / 100 g H2O

= [(238 + 32) / (238 + 32 + 2 (14 + 48))] X 108 g / 100 g H2O

= [(270) / (270 + 124)] X 108 g / 100 g H2O

= 74.01 g / 100 g H2O

100 g H2O + 474 g UO2(NO3)2

The volume of a

basement drain down tank sufficient to absorb the entire volume in

the dissolver, Tnx is: ________ We may need to be concerned about

accumulating a critical mass in the dissolver. Hence, we may need to

rethink these tank sizes. Note that the submerged tube surface area

must be consistent with the assumed heat transfer rate.

The TRU Concentration process has two major requirements for heat.

a) On each thermal cycle the contents of 14 tanks have to be raised from 20 degrees C to 100 degrees C;

b) On each thermal cycle the water content of one tank must be evaporated as part of the acid recovery process.

= -2739.5 Btu/lb of UO2(NO3)2

This is heat that must be provided to drive off the water. ??????

Hence: (1 Btu / lb) = 252.2 cal / 454 g = 0.5555 cal / g

Thus the heat required to recover UO2 from UO2(NO3)2.6H2O is:

2739.5 Btu/lb of UO2(NO3)2 = 2739.5 Btu/lb X (0.5555 cal / g) / (1 Btu / lb)

= 1522 cal / g of UO2(NO3)2.6H2O

Acid Recovery:

Each thermal cycle produces 108 g of UO2(NO3)2.6H2O. Thus the heat

required for UO2 recovery per thermal cycle is:

108 g X 1522 cal / g

= 164,376 cal

= 164,376 cal X 4.18 J / cal = 687,092 J

= 687,092 J X 1 W-s / J X 1 kWt / 1000 W X 1 h / 3600 s

= 0.1908 kWht

Thus the energy required per thermal cycle / 100 g H2O / tank is:

0.1908 kWht + 0.2666 kWht

= 0.45746 kWht / 100 g H2O / tank From above, each thermal cycle produces:

74.01 g UO2 / 100 g H2O

Thus at a facility processing 5000 kg / day of used CANDU

fuel has an average thermal power consumption of:

5000 kg / day X 1 day / 24 h X 0.47546 kWht/74.01 g X 1000 g / kg

= 1338.38 kWt

By the time fan and pump loads for heat removal are added and the

heat capacity of the tanks is included this will be about 2.0 MWt.

Note that this is an average heating power. In reality the system

heats for 80 minutes followed by a cooling period of 320 minutes.

Thus during the heating periods the peak power is 5X the average or:

5 X 2 MWt = 10 MWt.

Note that the UO2 / HNO3 recovery

unit can be run continuously. Hence about 800 kWt is needed

continuously and about 6 MWt are needed with a 20% duty cycle.

SOLVE FOR ACTUAL HEATING AND COOLING TIMES TANK REQUIREMENT:

Each

temperature cycle = 400 minutes. Number of temperature cycles per day

= [24 h X 60 m / h] / [400 min / cycle]

= 3.6 cycles / day

In order to produce 5000 kg / day of UO2, each cycle must produce:

5000 kg / 3.6 = 1389 kg UO2

Each 100 g of acid produces: 74.01 g UO2. Hence the

required number of 100 g units of acid per tank is:

1389 kg / 74.01 g = 18.77 X 10^3

Hence the required amount of acid / tank is:

18.77 X

10^3 X 100 g = 1877 kg

MISCELLANEOUS CASCADE DESIGN ISSUES:

Provide perforated sheet disks

in each tank to provide crystal growth surfaces and to prevent

crystals being sucked into the inlet of a backward pump. These must

be perforated all the way to their bottom edges to ensure complete

drainage. 5) It is necessary to carefully control the liquid

transfers to realize the optimum acid volume in each tank at a

particular time in the operating cycle. If there is too much acid in

a tank the system will be energy inefficient on thermal cycling and

the forward solute propagation will be poor. If there is too little

acid in a tank not all the crystals will be dissolved during a tank

heating cycle, leading to insufficient crystal growth in the next

tank during its cooling cycle. Thus the liquid levels must be

carefully controlled. Each tank should have a precise liquid level

sensing device and a pressure sensor at the tank discharge. The level

control in tank T1 is particularly important as it sets the levels in

the other tanks if the tank flows are all properly balanced. Thus the

lids must have provisions for the required

liquid level sensors. Â

SYSTEM SERVICE:

The envisaged cascade is orders of magnitude more

mechanically simple than the earlier student design summarized below.

From time to time the system will likely need mechanical service. To

safely enable such service both the HNO3 and the radioactive species

must be completely drained. To service the system heat the entire

system to 100 degrees C to dissolve all of the UO2(NO3)2. Lift out

the dissolver basket with a gantry crane and place it in a shielded

enclosure and then drain all the fluids from the drain valves below

the bottoms of the tanks to shielded below grade drain down tanks. If

the radiation from residue remaining in the system is too high flush

the system with clean 4.5 M nitric acid. Â

UO2(NO3)2 DATA:

MP = 60.2 deg C

Dissociation at 118 deg C

UO2(NO3)2 is hygroscopic forming 6(H2O), 3(H2O), 2(H2O)

TOXICITY OF UO2(NO3)2: 12 mg / kg (dog)

Natural Uranium:

U-238 99.27%, 4.47 X 10^9 Y

U-235 0.711%. 700 X 10^6 Y

U-234 ~ 0.019%

Price of uranium oxide ~ $28 / lb

PROCESS ECONOMICS:

Assume that we can process 7,900 ml of solution

per temperature cycle. That is a solution mass of:

(2.2 kg / 1000 ml) X 7,900 ml / cycle = 17.38 kg / cycle.

The weight of uranyl

nitrate hexahydrate UO2(NO3)2.6H2O processed per cycle is:

[(2.8 X 0.66) / 2.2] X 17.38 kg / cycle = 14.6 kg / cycle

Assume 6 temperature cycles per day:

5 cycles / day X 14.6 kg / cycle = 73 kg / day uranyl nitrate hexahydrate

Weight Fraction UO2 = UO2 / [UO2(NO3)2.6H2O]

= (238 + 32) / [238 + 32 + 2(62) + 6(18)]

= 270 / [270 + 124 + 108]

= 270 / 502

= 0.5378

Hence UO2 throughput = 73 kg /day X 0.5378

= 39.25 kg /day

With careful setup adjustment one TRU concentration system will process UO2 at 39.25 kg / day

yielding a TRU output of

39.25 kg / day X 4 g / kg = 157 g / day TRU.

Wiki indicates that The ultimate value of fissile is $7600 / kg

Thus the gross

value of this fissile fuel after pyroprocessing is:

0.157 kg/ day X $7600 / kg = $1193.42 / day

which must include the cost of

pyroprocessing.

Assume that the TRU concentration apparatus costs $500,000 and needs to earn a 2 year simple payback on capital plus $100,000 / year for cost of operation.

Gross income

is $1193.42 / day X 365 days / year = $435,598 year. Hence,TRU

concentration costs $350,000 / year leaving:

435,598 - 350,000 =

$85,598 / year

for pyroprocessing 157 gm / day TRU or .785 kg /

day of FNR core fuel.

One CANDU

reactor produces:

( 4 g TRU / kg UO2) X 100,000 kg UO2 / 1.5 years = 267

kg TRU / year

One TRU

concentrator produces:

0.157 kg TRU / day X 365 day / year = 57.3

kg / year

Thus we need:

267 / 57.3 = 4.66 TRU concentrators at $500,000 / TRU Concentrator for every CANDU

reactor.

PRIOR STUDENT WORK:

The

Ottensmeyer Plan originated in student work at the University of

Toronto circa 2010. The following notes are an edited version of

student work. There are various claims made by the students based on

references that should be confirmed before large sums of money are

committed to implementation of the process.

2.1.1 Fuel Bundle

Shearing CANDU nuclear fuel bundles are made from fuel pellets,

inserted into zircaloy cladded fuel rods and loaded into channels of

a cylindrical metal assembly (See Appendix B for diagram and

composition). Thus, the first step of reprocessing begins with the

removal of these long, narrow fuel rods from the bundle and

liberating the spent fuel. The proposed process achieves this by

mechanically shearing the rods into small segments, approximately 3cm

[6], and dissolving the exposed fuel in a hot nitric acid dissolver

solution.

Other alternatives for fuel liberation were considered,

such as chemical decladding, mechanical decladding and perforating

the cladding. Decladding proved uneconomical due to excess waste and

high losses, while perforating the cladding alone does not provide

enough exposed fuel surface area to dissolve it in a timely fashion

[6]. Sawing as an alternative to mechanical shearing was also

considered; however, it is less consistent and produces more metal

fines [7].

2.1.2 Dissolution The dissolver selected is a

countercurrent flow, multistage, rotary dissolver. After shearing,

pellets are fed into one end of the dissovler, while hot nitric acid

is fed into the other end at 4M and 95°C [6]. The

resulting solution, after dissolution of the spent fuel, is

approximately 300g/L (using U as a basis). The concentration and

temperature of nitric acid was found by analysis of calculated rate

data and experimental data (see Appendix C). While higher

concentrations of nitric acid yield higher rates of dissolution (75

minutes versus approximately 3 hours), it also introduces further

hazards with regards to acidity and corrosion. The dissolver stage

was not rate limiting in the process and thus the lower, less

hazardous acid concentration could be applied. As the dissolver drum

rotates, the pellets in the initial stage are transferred along its

length, while nitric acid flows counter-currently dissolving the fuel

within. The drum is rotated to propel the solids forward and moves in

a rocking motion to establish appropriate agitation for speedier

dissolution. It also allows for better mass transfer and more

efficient dissolution, as the least soluble fuel particles are

contacted with the strongest acid [7]. See Appendix E-1 for

schematic. At the last stage of the dissolver, the solid cladding is

ejected from the bottom, while the loaded nitric acid, containing

uranium nitrate, plutonium nitrate and other dissolved fission

products and actinides, flows out from the opposite end. The main

dissolution reactions (Rxn. 1 and 2) are the dissolution of uranium

dioxide (UO2) in nitric acid. Rxn. 2 is dominant when nitric acid

concentration is less than 10M [7]. The other actinides dissolution

reactions proceed similarly. UO2+ 4HNO3 = UO2(NO3)2+ 2NO2+ 2H2O

ΔHr°= -74.9 kJ/mol [Rx.1] 3UO2 + 8HNO3 =

3UO2(NO3)2 + 2NO + 4H2O ΔHr°= -367.6 kJ/mol

[Rx.2] During dissolution, NOx gases and radioactive iodine vapours

from the fuel are emitted and sent for gas treatment (see section

6.2) while the concentrated solution is sent for crystallization. The

undissolved cladding is rinsed, monitored for fissile material,

packaged and transferred to the solid waste storage area for

disposal.

This dissolver design is an update on more traditional

spent fuel dissolvers that involve placing pellets into perforated

baskets, followed by immersion in hot nitric acid. There are a number

of operating limitations associated with this method, including the

requirement of batch processing. Furthermore, the use of a highly

corrosive solvent, off-gas emissions, as well as the potential for

criticality, leads to challenges and limitations on the amount

processed per batch. The equipment also decreases any criticality

risk due to the processing of less mass in one location and its long,

narrow geometry [7].

2.1.3 Crystallization and Clarification The

dissolver solution contains both long lived actinides used for FNR

fuel and shorter-lived fission products. Before separation of

actinides from fission products, the majority of U can be

crystallized out of solution directly into Uranyl Nitrate Hexahydrate

(UNH), a yellow green crystal. Due to its high concentration of U in

solution (300g/L present as uranyl ions, UO22+), as well as its

relative insolubility, a decrease in solution temperature to 10-20°C

is capable of crystalizing approximately 70-80 wt% of the U [8].This

was determined based on solubility-temperature data, as well as

experimental results (see Appendix D). Co-crystallization of smaller

amounts of Pu(VI) and Np(VI) is possible and favourable, as this

would further diminish the amount of actinides requiring later

processing. The crystallization reaction proceeds as follows: UO22++

2NO3- + 6H2O = UO2(NO3)2•6H2O ΔHr°=

-20 kJ/mol [Rx.3] One issue with crystallization is the contamination

of U with fission products. Testing has shown that there is

negligible occlusion of fission products within the crystals, and

crystals can be washed to achieve a decontamination factor of about

100 for fission products (after 3 wash cycles) [8]. Washing is done

with cooled water in the last stages of a multistage crystallizer.

Although crystallization prior to extraction is not carried out in

conventional PUREX, this modified process uses it to reduce the

amount of aqueous and organic solution being processed. This addition

provides process and economic benefits (e.g. less process fluid), as

well as environmental benefits as the corresponding liquid waste

requiring treatment and disposal is reduced. While it may be possible

to achieve greater amounts of U crystallization with lower

temperatures (i.e. ~99% at -30°C [8]), liquid-liquid

extraction equipment (see Section: 2.1.4 Main Liquid-Liquid

Extraction and Stripping) would still be required to achieve

separation of the remaining actinides. The smaller temperature

reduction for approximately 70% U crystallization maximizes the

benefit of crystallization, without incurring unnecessary costs and

complexities. Before proceeding to the main extraction stage the

exiting dissolver solution must be clarified, also by centrifugation,

to remove any suspended particles that may interfere in extraction.

The collected particles are recycled for further dissolution. The

dissolver solution then proceeds to a mixing tank for acidity and

concentration adjustment, mainly to maintain the high concentration

of nitric acid (approximately 5-6M) required for high efficiency

separation in the main extraction stage [4]. The UNH crystals which

exit the crystallizer as a slurry, are gravity fed into a mixing tank

for further processing (see section 2.1.7 Metal Formation for more

details). The crystallizer selected is an annular, rotary,

screw-type, continuous crystallization device, with a cooling jacket

for temperature control. This design was selected due to its

continuous operation and its similarity in functioning to the other

screw-type equipment used in the overall process. The crystallizer

was designed to operate at an incline to aid in nucleation and growth

of crystals. This also facilitates easier removal of crystals without

damage. As the internal spiral blades rotate they dislodge the

crystals growing on the wall and move them upward to a centrifugal

basket for washing and filtration, while the remaining dissolver

solution flows downward. The rotary screw design, in a similar way to

the rotary dissolver, also provides compartments or stages that allow

for crystal washing to be done internally. See Appendix E-1 for

schematic. One operational disadvantage of the crystallizer design is

the potential for crystal accumulation and blockage of discharge

streams. This can be mitigated by appropriate operation. For example,

the screw rotation, dissolution feed and coolant feed can be adjusted

to restrict new crystal growth or break down crystal agglomerates.

Scrub acid may also be fed to decompose any crystal blockages [9]

(see Section 3. for more details).

2.1.4 Main Liquid-Liquid

Extraction and Stripping After crystallization, clarification and

concentration, the dissolver solution is ready for the main

liquid-liquid extraction and stripping. The solution is fed into the

middle of a multistage centrifugal contactor to begin the separation

of the remaining actinides from fission products. [4] M. Nakahara, Y.

Sani, Y. Koma, M. Kamiya, A. Shibata, T. Koizumi and T. Koyama,

"Separation of Actinide Elements by Solvent Extraction Using

Centrifugal Contactors in the NEXT Process," J Nucl Sci Technol,

vol. 44, no. 3, pp. 373-381, 2007. [5] J. D. Law, T. G. Garn, D. H.

Meikrantz and J. Warburton, "Pilot-Scale TRUEX Flowsheet Testing

For Separation of Actinides and Lanthanides from used Nuclear Fuel,"

Separation Science and Technology, vol. 45, pp. 1769-1775, 2010. [6]

H. M. Mineo, H. Isogai, Y. Morita and G. Uchiyama, "An

Investigation into Dissolution Rate of Spent Nuclear Fuel in Aqueous

Reprocessing," J. Nucl. Sci. Technol., vol. 41, no. 2, pp.

126-134, 2004. [7] R. Jubin, "Spent Fuel Reprocessing," in

Introduction to Nuclear Chemistry and Fuel Cycle Separations Course,

Consortium for Risk Evaluation With Stakeholder Participation,

Nashville, 2008. [8] T. Takata, Y. Koma, Sato, Koji, Kamiya,

Masayoshi, A. Shibata, K. Nomura, H. Ogino, Koyama, Tomozo and S.-i.

Aose, "Conceptual Design Study on Advanced Aqueous Reprocessing

System for Fast Reactor Fuel Cycle," J Nucl Sci Technol, vol.

41, no. 3, pp. 307-314, 2004. [9] K. Ohyama and K. Nomura,

"Development of Uranium Crystallization System in “NEXTâ€ン

Reprocessing

Process," in Proceedings of International Conference on Advanced

Nuclear Fuel Cycles and Systems, Boise, 2007. Â Appendix

D: Crystallization of Uranium in Nitric Acid Data The following graph

depicts the solubility of uranium in nitric acid, as a function of

uranium and nitric acid concentration, plus temperature. Moving from

right to left, the uranium concentration decreases with temperature

before reaching a minimum point, where water and nitric acid

crystallize. To avoid this co-crystallization, a crystallizer must

operate to the right of this point. The graph shows that as the

concentration of nitric acid increases, the minimum point shifts from

right to left and a higher UNH crystallization is possible. To

maximize crystallization, the feed uranium and nitric acid

concentration should be maximized as well [6]. Figure 3 Solubility

Curves of Uranyl Nitrate The above equilibrium data is supported by

experimental data. Crystallization tests at high uranium

concentration (300-600 g/l) and high nitric acid concentration (4-6M)

to simulate spent fuel dissolver solution have yielded 70-80% uranium

recovery at 10-20°C, and up to 95% at -10°C

[7]. The results for a run with 500g U/l and 5M nitric acid are

summarized below: Figure 4 Uranium and nitric acid concentration in

mother liquor (left) and recovery of uranium (right) Appendix E-1:

Equipment Diagrams The following appendix features schematic diagrams

of certain non-standard key equipment to aid in the visualization and

understanding of their functioning, as described in Section 2.1 of

the Process Description, and also as discussed in the non-key unit

sizing section. Figure 5 Fuel Bundle Shearer [8] Figure 6 Continuous

Rotary Dissolver [9] Figure 7 Rotary Crystallizer Crystallizer is

scaled down from a tested device, having a feed rate of 1380L/hr and

a residence time of 1 hour [6]. The dimensions of internal rotary

cylinder with the blades of the tested crystallizer device are 11

centimeters of internal diameter and 50 centimeters by length [2].

Since the amount of uranium crystals to be dealt with is much less,

the dimensions are rescaled by reducing the original volume of

0.00475m3 by half to 0.002375m3 in order to design for smaller

blades. Cost Table Appendix T: Works Cited for Appendices [1]

Advamacs, "Concentration Calculator," [Online]. Available:

http://www.trimen.pl/witek/calculators/stezenia.html. [Accessed

November 2012]. [2] D. P. Jackson, "NWMO Background Papers:

Technical Methods; Status of Nuclear Fuel Reprocessing, Partitioning,

and Transmutation," NWMO, 2003. [3] D. Hart and D. Lush, "THE

CHEMICAL TOXICITY POTENTIAL OF CANDU SPENT FUEL," NWMO, 2004.

[4] L. Johnson and J. Tait, "Source terms for 36Cl in the

assessment of used fuel disposal," Atomic Energy of Canada

Limited Technical Record, 1992. [5] J. Tait, I. Gauld and G. Wilkin,

"Derivation of Initial Radionuclide Inventories for the Saftey

Assessment of the Disposal of Used CANDU Fuel," Atomic Energy of

Canada Limited Report, 1989. [6] G. Faure, Principles and

Applications of Geochemistry, Upper Saddle River: Prentic Hall Inc.,

1998. [7] R. Hart and G. Morris, "Crystallization temperatures

of uranyl ntirate-nitric acid solutions," Prog. Nucl. Energy

III, p. 544, 1958. [8] T. Chikazawa, T. Kikuchi, A. Shibata, T.

Koyama and S. Homma, "Batch Crystallization of Uranyl Nitrate,"

J. Nucl. Sci. Technol., vol. 45, no. 6, pp. 582-587, 2008. [9] T.

Todd, "Spent Nuclear Fuel Reprocessing," in Nuclear

Regulatory Commission Seminar, Rockville, 2008. [10] R. Jubin, "Used

Fuel Reprocessing," in CRESP Nuclear Fuel Cycle Course, 2011.

[11] Rousselet-Robatel, "ROUSSELET ROBATEL MODEL LX MULTISTAGE

CENTRIFUGAL EXTRACTOR," [Online]. Available:

http://www.rousselet-robatel.com/products/pdfs/multistage-centrifugal-extractor-operatingprinciple.

pdf. [Accessed 2012]. [12] P. A. Haas, R. D. Arthur and S. W.B.,

"Development of Thermal Denitration to Prepare Uranium Oxide and

Mixed Oxides for Nuclear Fuel Fabrication," Oak Ridge National

Laboratory, Oak Ridge, 1981. [13] S. Jeong, S. Park, S. Honge, S.

C.S. and S. Park, "Electrolytic production of metallic uranium

from U3O8 in a 20kg batch scale reactor," J. Radioanal. Nucl.

Chem., vol. 268, no. 2, pp. 349-356, 2006. [14] T. Takata, Y. Koma,

Sato, Koji, Kamiya, Masayoshi, A. Shibata, K. Nomura, H. Ogino,

Koyama, Tomozo and S.-i. Aose, "Conceptual Design Study on

Advanced Aqueous Reprocessing System for Fast Reactor Fuel Cycle,"

J Nucl Sci Technol, vol. 41, no. 3, pp. 307-314, 2004. [15] R. Herbst

and M. Nilsson, "Standard and advanced separation: PUREX

processes for nuclear fuel reprocessing," in Advanced Separation

Techniques for Nuclear Fuel Reprocessing and Radioactive Waste

Treatment, 2011, pp. 141-173. This web page last updated June 21,

2021 A^4 B^2 I Tsors. Â

This web page last updated December 30, 2020